2024-05-25 hits:0 source:corten steel fabricators

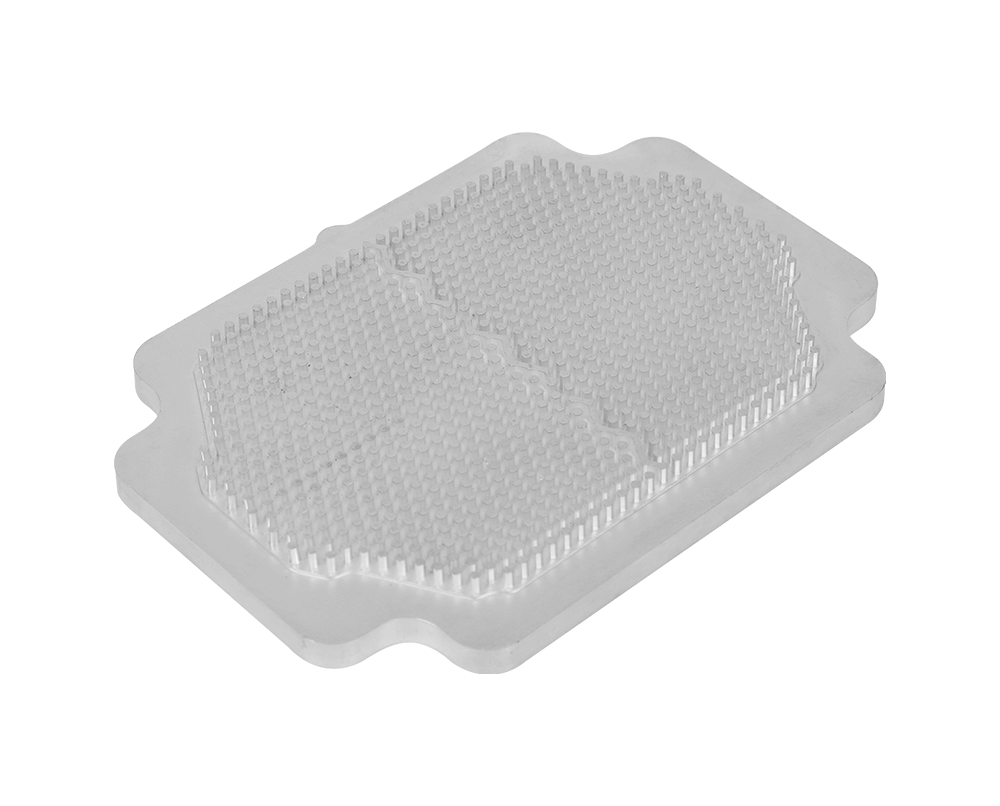

Aluminum alloy die castings are one of the most commonly used die castings in the die casting industry, characterized by high strength, small specific gravity, and strong corrosion resistance. However, aluminum alloy die castings may also have some defects due to the characteristics of aluminum alloy. For example, due to the adhesive properties of aluminum alloy, some coatings need to be sprayed in the cavity of the die casting mold to help the aluminum alloy die castings demold. However, this operation sometimes leads to some patterns on the surface of the aluminum alloy die castings

The pattern appearing on the surface of aluminum alloy die-casting parts is a defect, but this defect can be easily solved. The formation of the pattern is caused by excessive coating spraying or poor coating quality. To solve this problem, it is necessary to choose the appropriate coating and adjust the amount of coating; This problem can also be solved by increasing the temperature of the die casting mold; It can also be solved by adjusting the speed and pressure of the inner runner. Although aluminum alloy die castings are prone to defects, due to their low density, the cost of raw materials is lower, and because they are difficult to die cast, the value of aluminum alloy die castings is generally higher. Solving the defects of aluminum alloy die castings will bring greater returns to the die casting factory.

Read recommendations:

aluminum project box enclosure.Impressions of defects in aluminum alloy die-casting