The purpose of improving the service life of zinc alloy die-casting molds For many zinc alloy die

Aluminum alloy die-casting oxidation treatment Why can't your family do oxidation treatment for a

Who says aluminum alloy die-casting is not environmentally friendly? You may know something about

Good aluminum alloy die-casting molds can be worry free, labor-saving, and cost-effective Aluminu

Aluminum alloy die-casting molds are more cost-effective in this way Do you need to set up an alu

There is still significant room for improvement in aluminum alloy die-casting, which is worth a tr

Which is more suitable for you, zinc alloy die-casting or aluminum alloy die-casting (1) Zinc all

How to prevent spots from appearing on aluminum alloy die-casting parts Aluminum alloy die-castin

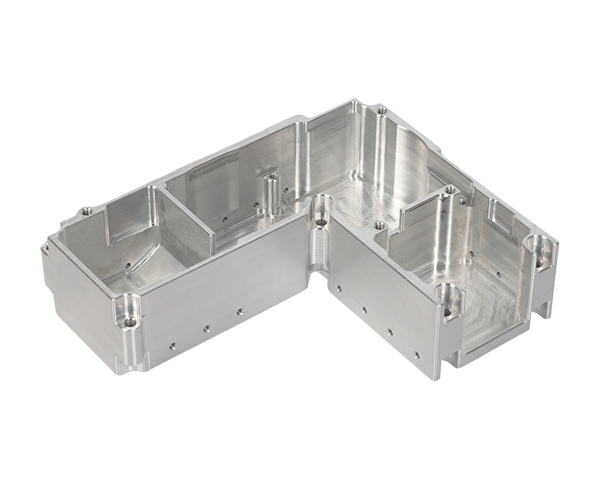

Precision die-casting machining starts with selecting the right materials There are three element

The method of shedding excess fat on the body through die-casting parts During the production and

The Future of Aluminum Alloy Die Casting Industry Since the reform and opening up, the aluminum

A Brief Discussion on the New Trends of Future Die Casting Factory Development In recent years, b

To make good die-casting molds, material inspection is essential Die casting molds are essential

Whether the die-casting factory is specialized or not can be seen from these aspects Die casting

The Mystery of Gas Source in Die Casting Parts Die casting is a metal product produced using die-

Choosing a die-casting processing factory is as simple as buying groceries The die-casting parts

Why are the zinc alloy die-casting parts made by this die-casting factory so "beautiful" Everyone

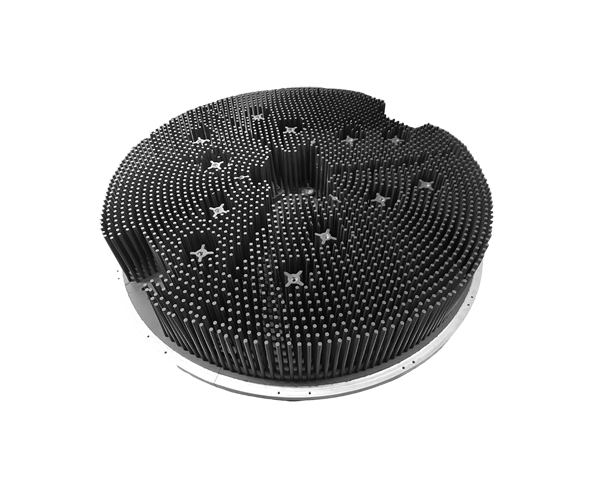

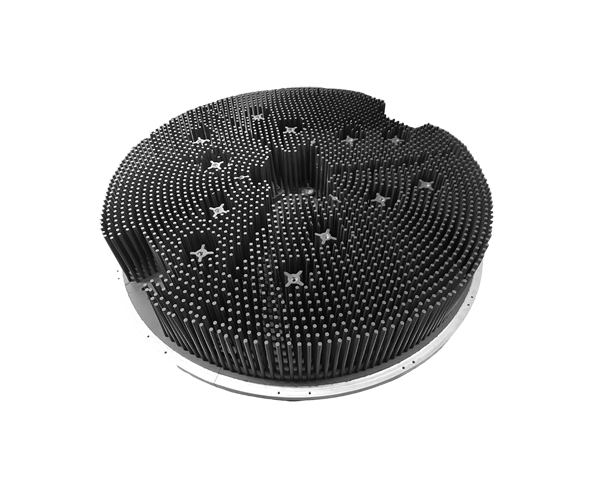

Want aluminum alloy die-casting molds to have a long lifespan The application of aluminum alloy d

Die casting factory helps you distinguish between decompression casting machines The most valuabl

What processes can be used for corrosion prevention? Due to the characteristics of aluminum alloy