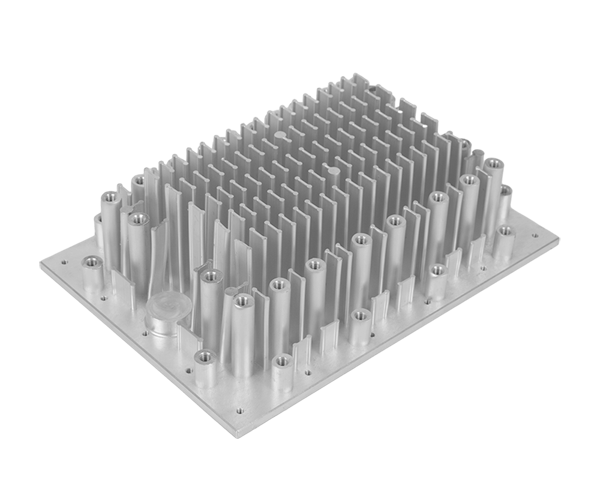

The Use of Die Castings in Automotive Accessories Die castings play a vital role in the productio

What Are Automotive Aluminum Die Castings? Automotive aluminum die castings play a crucial role i

Surface Treatment Methods for Automotive Die-Cast Aluminum Parts Automotive die-cast aluminum par

Fan Lamp Die Casting Parts Fan lamp die casting parts are specifically designed for use in the ma

Automotive aluminum oxide parts have become increasingly significant in the automotive industry.

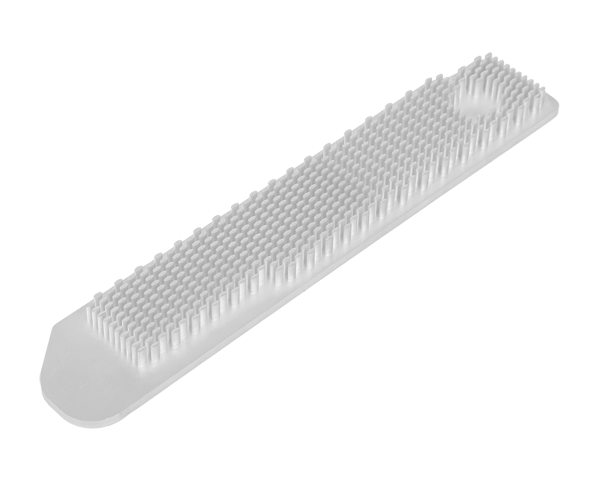

Die casting accessories consumables are essential items that are used in the die casting process

Die casting mold accessories are essential components that contribute to the efficient and high-

Aluminum C-Channel Profiles, also known as C-profiles or U-channels, are an aluminum alloy profile

Aluminum Caravan Extrusions are aluminum alloy extrusions designed for the manufacture and assembl

Precision aluminum extrusion refers to aluminum alloy profiles manufactured through a high-precisi

Aircraft Aluminum Extrusions are high-performance aluminum alloy extrusions designed and manufactu

Bulk purchases of aluminum extrusions are essential for construction, industrial manufacturing, tr

20 x 40 mm aluminum extrusion is a standard size commonly used in industrial and architectural app

Aircraft Aluminum Extrusion is a high-performance aluminum alloy profile designed and manufactured

Schluter Quadec Matte Black is a high-quality edge treatment and decorative profile produced by Sc

To find aluminum extrusion suppliers or manufacturers near you, you can take the following approac

Slotted Aluminum Extrusion is an aluminum alloy profile widely used in fields such as construction

Aluminum Window Extrusions are widely used materials in modern buildings, and are favored for thei

Bending Aluminum Extrusions is the process of processing standard or customized aluminum profiles

Aluminum flashing profiles are key components used in buildings to prevent moisture penetration an