2024-08-06 hits:0 source:corten steel fabricators

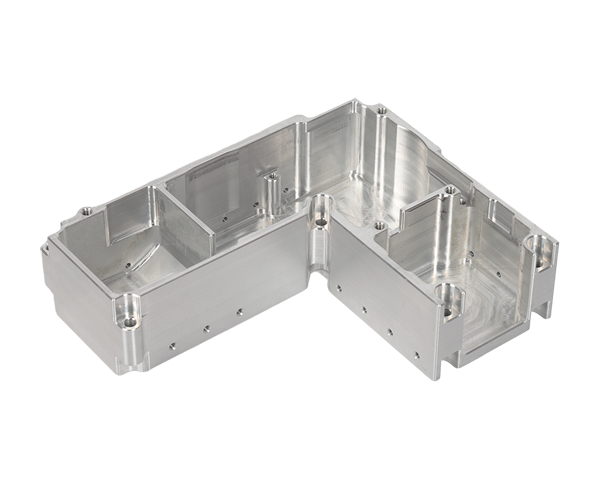

Aluminum alloy die-casting oxidation treatment

Why can't your family do oxidation treatment for aluminum alloy die-casting? "When faced with such a question from a customer, the customer service is helpless. So why can't oxidation treatment be done for aluminum alloy die-casting? Let professionals answer for you!

The anodized film of aluminum has high hardness, good corrosion resistance and wear resistance, and also has good transparency, thus maintaining the original metallic texture of aluminum on the surface after anodizing treatment. However, aluminum alloy die-casting materials contain a lot of metal materials, which can easily cause defects such as air streaks, cold shuts, and sand holes during the surface treatment of aluminum alloy die-casting parts. Due to the different electrode potentials between the second phase generated by alloying elements and the aluminum substrate, the anodizing behavior and mechanism of aluminum alloy are much more complex than pure aluminum. At the same time, the composition of aluminum alloy anodized film, in addition to aluminum oxide and anions in the solution, will inevitably contain some alloying elements in the aluminum alloy, which exist in the form of elemental, oxide, or intermetallic compounds. So the appearance quality of aluminum alloy die-casting products after oxidation treatment is poor and the defect rate is high.

Read recommendations:

2020 v slot aluminium extrusion

Large Aluminum Cold Forged Pin Fin Radiator