2024-08-06 hits:0 source:corten steel fabricators

Good aluminum alloy die-casting molds can be worry free, labor-saving, and cost-effective

Aluminum alloy die-casting molds are essential for the production of aluminum alloy die-casting parts. The quality of die-casting parts is directly related to the die-casting molds, and due to the high melting point and corrosion characteristics of aluminum alloys, the cost of mold opening is very high. Opening a normal set of aluminum alloy die-casting molds costs 20000 to 30000 yuan, which makes many people hesitate. However, those who understand the situation know that using a good set of aluminum alloy die-casting molds can save oneself worry, effort, and money.

Because good aluminum alloy die-casting molds have the advantages of long service life, high efficiency, high dimensional accuracy, and good stability, using such die-casting molds can improve the quality, production efficiency, and yield of die-casting parts. This is a long-term investment with long-term returns, allowing you to have no worries about quality and delivery time.

Using inferior aluminum alloy die-casting molds may seem to save money, but in the later production process, continuous investment is required. In terms of yield rate, it can already offset the money saved during mold opening, and your die-casting products are constantly threatened by quality and delivery time.

Read recommendations:

aluminium window trim profiles

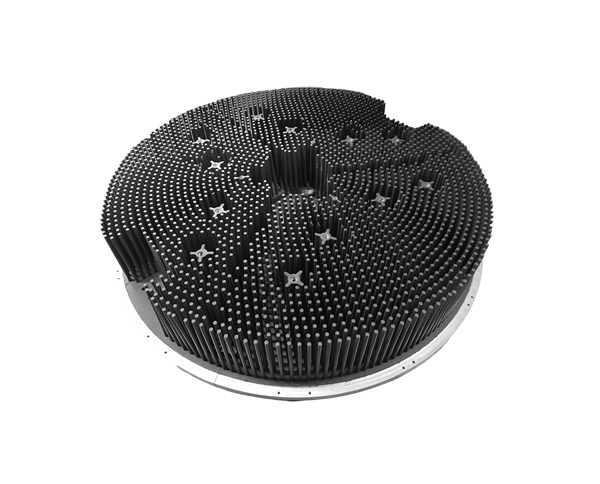

Large Aluminum Cold Forged Pin Fin Radiator

aluminum forging manufacturers

What to do if there is a cold lap on the surface of zinc alloy die-casting parts

Design of Aluminum Alloy Die Casting Mold.mikrotik omnidirectional antenna