2024-06-27 hits:0 source:corten steel fabricators

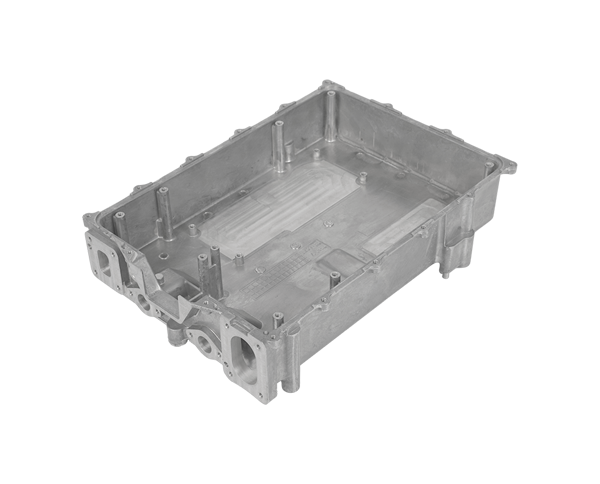

In the context of intelligent manufacturing, CNC die casting technology is becoming a powerful engine driving industrial development. It integrates advanced CNC technology, automated operations, and high-precision machining, bringing unprecedented possibilities to the manufacturing industry.

Firstly, CNC die casting technology can precisely control every action and parameter during the die casting process through a precise CNC system, ensuring that the produced components meet strict dimensional and quality requirements.

Secondly, the automation level of CNC die casting technology is very high. It can achieve unmanned continuous production, greatly improving production efficiency and reducing reliance on manual labor.

Once again, CNC die casting technology can cope with complex and ever-changing market demands. It can quickly adjust production plans, adapt to small batch and multi variety production modes, and meet customer customization needs.

Finally, CNC die casting technology has also promoted the improvement of enterprise efficiency. By reducing scrap rates, improving production efficiency, and reducing labor costs, it directly enhances the profitability and market competitiveness of enterprises.

In summary, CNC die casting technology has become an important engine for promoting intelligent manufacturing due to its high precision, high efficiency, flexibility, and intelligent automation characteristics. With the continuous innovation of technology and the expansion of application fields, CNC die casting will play an increasingly crucial role in the future manufacturing industry.

Read recommendations:

custom extruded aluminum profiles

custom aluminum sheet fabrication