2024-05-07 hits:0 source:corten steel fabricators

Die-casting mold factories are specialized manufacturers of various die-casting molds, usually serving die-casting factories or customers who need customized die-casting parts. After the die-casting mold factory produces the die-casting mold, there is an acceptance process, which is a test of the qualification of the die-casting mold. Outsiders usually do not understand what to check, only experts know what to check.

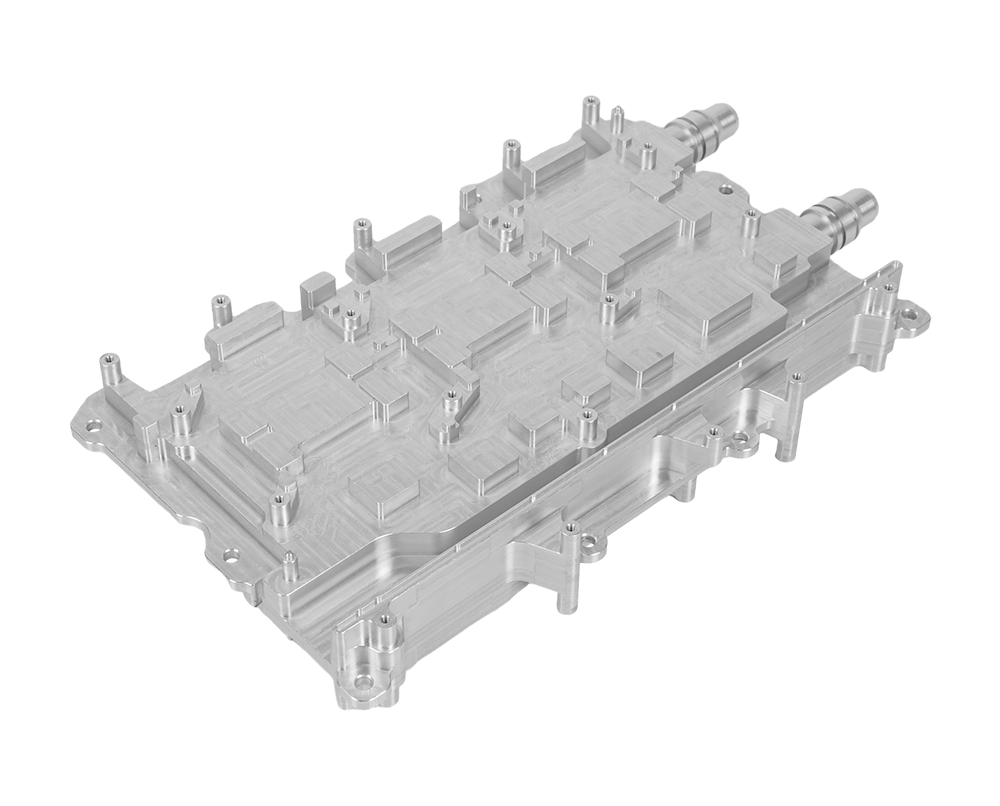

When accepting the molds made by this die-casting mold factory, the first thing to check is safety. Safety production is the foundation of an enterprise. In terms of safety, we need to check the waterproofing of lifting holes, slider springs, travel switches, and the accuracy of reset hole threads; The next step is to inspect the dimensions of various parts of the die-casting mold and the external connections; Next is the inspection of appearance and labeling; Finally, there is a trial mold inspection, which can visually check the working status of the die-casting mold. If any problems are found during the inspection, the die-casting mold factory should be requested to make modifications, because once it is signed for, any further problems will incur the cost of the modifications themselves.

Read recommendations: