2024-07-16 hits:0 source:corten steel fabricators

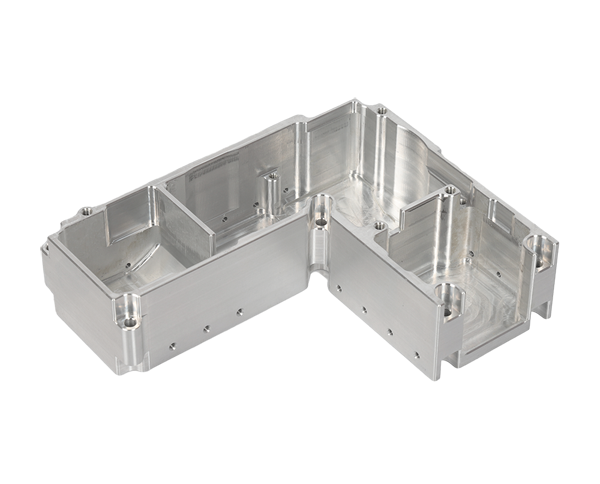

As a basic manufacturing process, die-casting parts processing has certain technical requirements. Without a certain amount of knowledge reserves and experience, it is impossible to make good die-casting parts. Although advanced die-casting machines have solved many problems with the improvement of scientific and technological levels, they have also increased the production costs of die-casting plants. In order to increase profits, improve product quality and yield, it is important to understand the key points of die-casting processing

People engaged in the die-casting industry know that there are three cornerstones for die-casting processing, namely die-casting molds, raw materials, and die-casting machines. There is not much to say about die-casting machines and raw materials, just buy a better one. However, die-casting molds are worth studying. Die-casting molds are the place where die-casting parts are formed, which is crucial to the entire die-casting process and directly affects the quality and yield of die-casting parts. A good die-casting mold can make the entire die-casting process fast and good, so the production of die-casting molds is the focus of die-casting processing.

Read recommendations:

precision stamping parts manufacturers

metal fabrication services.Smooth plating of aluminum alloy die casting