2025-01-03 hits:0 source:corten steel fabricators

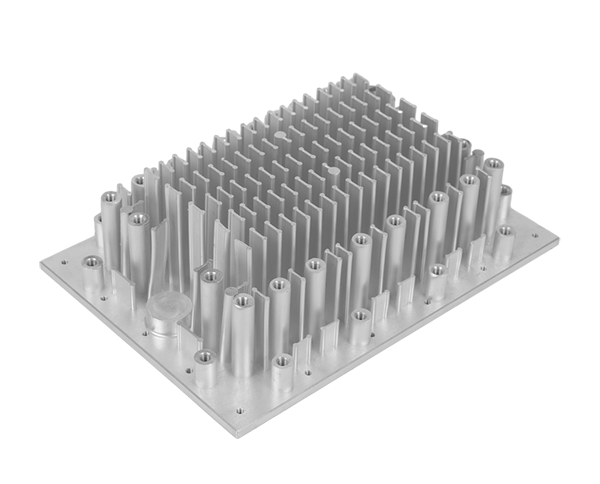

Die casting mold accessories are essential components that contribute to the efficient and high-quality production of die cast parts. These accessories can vary depending on the specific requirements of the die casting process and the type of mold being used.

One common die casting mold accessory is the ejector pin. Ejector pins are used to push the finished die cast part out of the mold cavity after the casting process is complete. They are typically made of hardened steel and are designed to withstand the high pressures and temperatures involved in die casting.

Another important accessory is the cooling system. Die casting molds need to be cooled quickly to prevent the molten metal from solidifying too slowly and causing defects in the finished part. Cooling systems can include water channels, cooling lines, and heat exchangers.

Sprue bushings are also a key die casting mold accessory. They are used to guide the molten metal into the mold cavity and ensure a smooth flow. Sprue bushings are typically made of hardened steel or copper and are designed to withstand the high temperatures and pressures of the die casting process.

these accessories, there are many other components that may be used in die casting molds, such as guide pins, bushings, and parting line locks. These accessories all play important roles in ensuring the accuracy and quality of the die cast parts produced.

die casting mold accessories are crucial for the successful production of high-quality die cast parts. From ejector pins to cooling systems and sprue bushings, these accessories help to ensure that the die casting process runs smoothly and efficiently.

Read recommendations:

4040 aluminum t slot extrusion

aluminium corrugated sheet price