2024-05-13 hits:0 source:corten steel fabricators

Aluminum alloy die-casting is one of the most common processes in the die-casting industry. Due to the excellent characteristics and wide applicability of aluminum alloy die-casting, there is a great demand for aluminum alloy die-casting parts in the market, especially in the automotive manufacturing industry. Domestic die-casting manufacturers need to produce millions of tons of aluminum alloy die-casting parts every year. Do you know that there is a huge business opportunity in the aluminum alloy die-casting industry? Seizing this opportunity and becoming rich overnight is really not a dream.

As I am currently working at a Shenzhen die-casting factory, which specializes in customizing zinc alloy die-casting parts and aluminum alloy die-casting parts, I have some understanding of the aluminum alloy die-casting industry. There is a process called anodizing in the aluminum alloy die-casting industry, and many people have approached my die-casting factory, hoping that we can help them produce aluminum alloy die-casting parts that use anodizing technology. However, due to the high requirements of anodizing technology on the material of aluminum alloy die-casting parts, the yield rate of this process is very low and it is very difficult to operate. Therefore, my die-casting factory can only reluctantly refuse them.

Read recommendations:

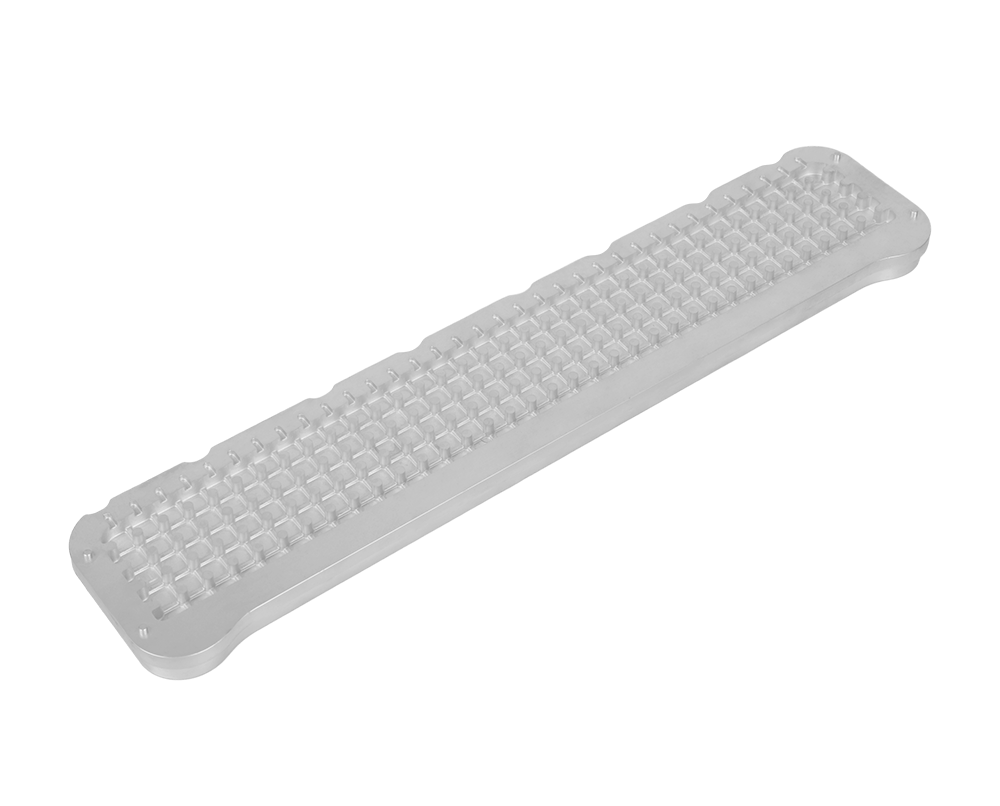

extruded aluminum stair nosing

Industrial Aluminum Profile Extrusion company

aluminum extrusions for screen enclosures

This is something that aluminum alloy die-casting factories need to do before opening the mold