2024-05-10 hits:0 source:corten steel fabricators

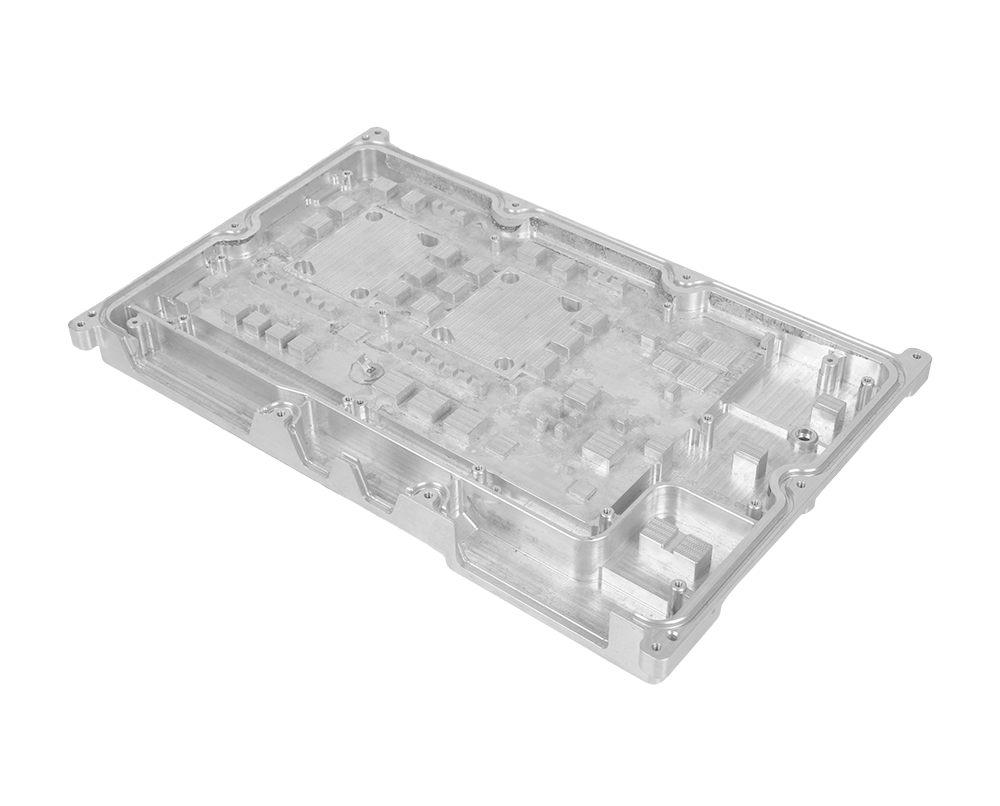

Because trial molding refers to the testing and production steps carried out in the product development and manufacturing process after the completion of mold production and before mass production. After completing all accessories and assembling, the mold needs to undergo actual die-casting processing and obtain die-casting samples, which can then be tested to determine whether the mold production fully meets the design requirements. If the sample produced by die-casting fully meets the design requirements, it indicates that the mold production is not a problem and can be put into mass production; Otherwise, it is necessary to modify the mold based on the feedback from the sample. Depending on the situation of mold modification, trial molds may be conducted multiple times before mass production until all issues are completely corrected by the mold.

Die casting trial mold is to make sufficient preparations for mass production in the later stage. Only by doing enough preparation work can the quality of mass production in die casting processing be guaranteed, and the production efficiency of mass production can also keep up. Therefore, when looking for a die casting factory, we can find a manufacturer that can independently open molds, which will be more conducive to efficient production in the later stage!

Read recommendations:

Materials of Thermal Break Strips for Door and Window Aluminum Profiles

General maintenance methods for aluminum alloy die-casting molds.aluminium die casting auto parts