2024-06-05 hits:0 source:corten steel fabricators

A good aluminum alloy die casting can only be formed after passing many assessments. In order to avoid the occurrence of unqualified aluminum alloy die castings, the following requirements must be followed.

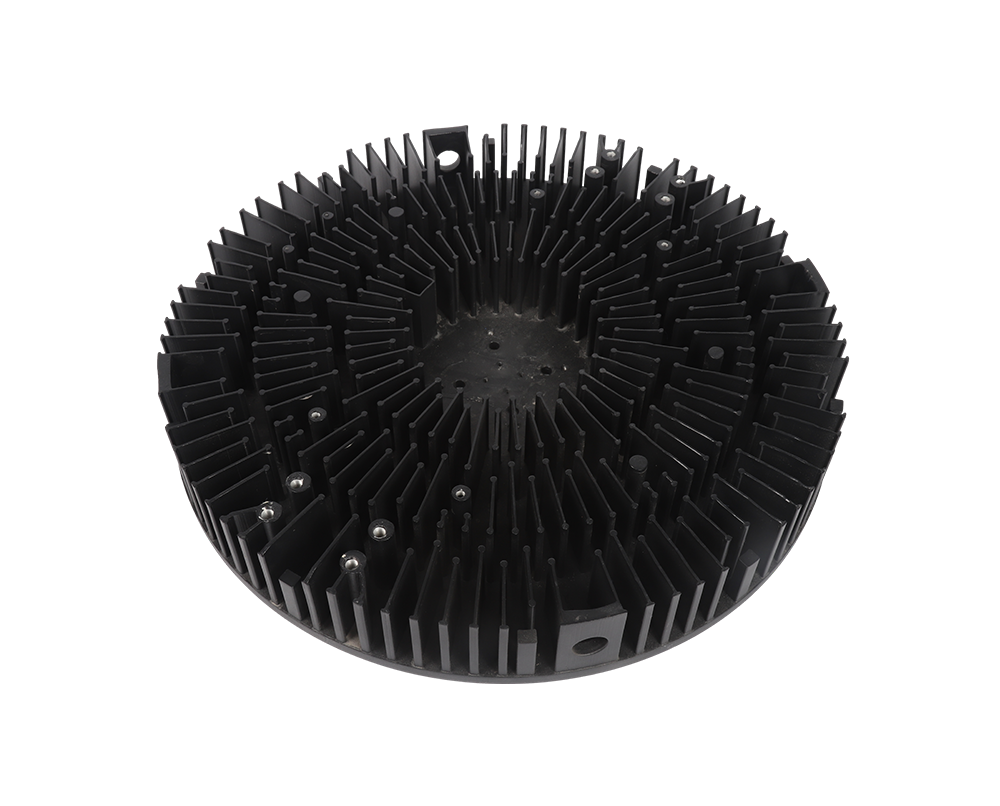

The various requirements for aluminum alloy die castings include: 1. No defects are allowed in the die castings, including cracks, uncast, looseness, bubbles, and any penetrating defects, as well as wear, dents, network burrs, etc. Defects can easily cause damage to the die castings and increase the defect rate. 2、 Aluminum alloy die-casting parts must not have triangular defects such as scratches, dents, broken flesh, and mesh burrs, and the integrity of the die-casting parts must be ensured. 3、 The geometric shape and dimensions of die castings should meet the requirements of the casting drawings to avoid scrap. If there are special requirements, they need to be indicated on the drawings. 4、 If surface treatment is required for die castings, such as polishing, spraying, etc., it should be consistent with the requirements on the drawing.

Read recommendations:

Aluminum alloy die casting mold maintenance tips.cold chamber high pressure die casting