2024-06-04 hits:0 source:corten steel fabricators

In the production process of aluminum alloy die-casting, the cracking problem of aluminum alloy die-casting molds is quite common. Therefore, it is important to prevent the cracking problem of aluminum alloy die-casting molds by doing these points well!

1. Due to the high temperature of aluminum alloy die-casting molds during the die-casting production process, it is best to add a cooling system, which is very helpful for the continuous use of the mold.

2. During the production process of aluminum alloy die-casting molds, improper spraying of release agents can also cause significant damage to the production molds, so attention should be paid during the production process.

3. Poor heat treatment of aluminum alloy die-casting molds is a common problem, mainly due to hardness. Generally, if the hardness is not less than HRC-47, problems will not occur.

The reasonable use of aluminum alloy die casting molds is very important, which not only affects the quality of die casting products, but also affects the production efficiency of aluminum alloy die castings! So for the cracking problem of aluminum alloy die-casting molds, it is important to take the above three preventive measures!

Read recommendations:

aluminium window frame profiles

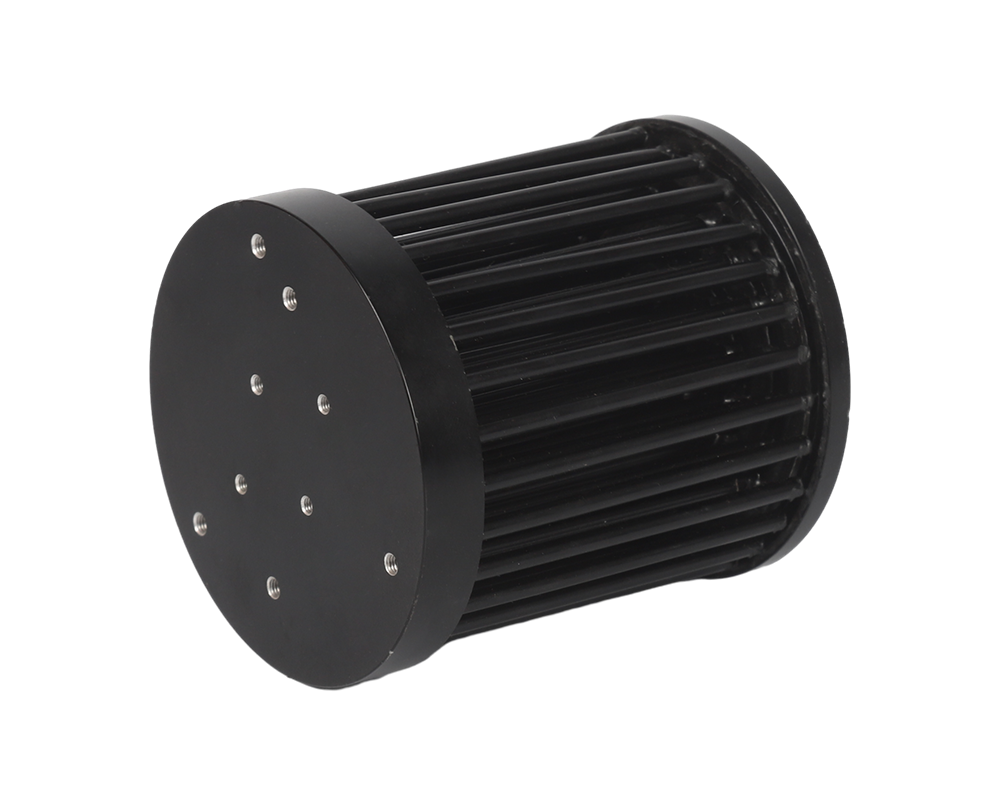

LED Cold Forged Downlight Radiator