2024-05-11 hits:0 source:corten steel fabricators

Leakage of zinc alloy die-casting parts is a manifestation of defects in die-casting parts. In the face of casting leakage, die-casting plants need to take measures to deal with it and actively prevent it. So, how do experienced die-casting plants solve it?

After the airtightness test of the die-casting parts after processing, there may be water leakage, which may be caused by unreasonable casting structure, incorrect material selection, poor exhaust or thin casting wall. Based on these reasons, die-casting factories with rich die-casting experience will take the following measures according to the specific situation: first, judge whether the structure is suitable for production based on the design drawings, replace the casting structure before production, reduce the wall thickness, and then select reasonable materials according to the characteristics of the product, reduce the melting temperature, etc. The pressure testing equipment for detecting water leakage in die-casting parts is also important. Strengthen protection during use to prevent damage. If equipment damage is found, repair should be carried out in a timely manner. If the pressure testing equipment is damaged, it cannot accurately detect the problem of water leakage in die-casting parts, which brings trouble to subsequent processing.

Read recommendations:

aluminum window extrusions suppliers

architectural sheet metal fabrication manufacturer

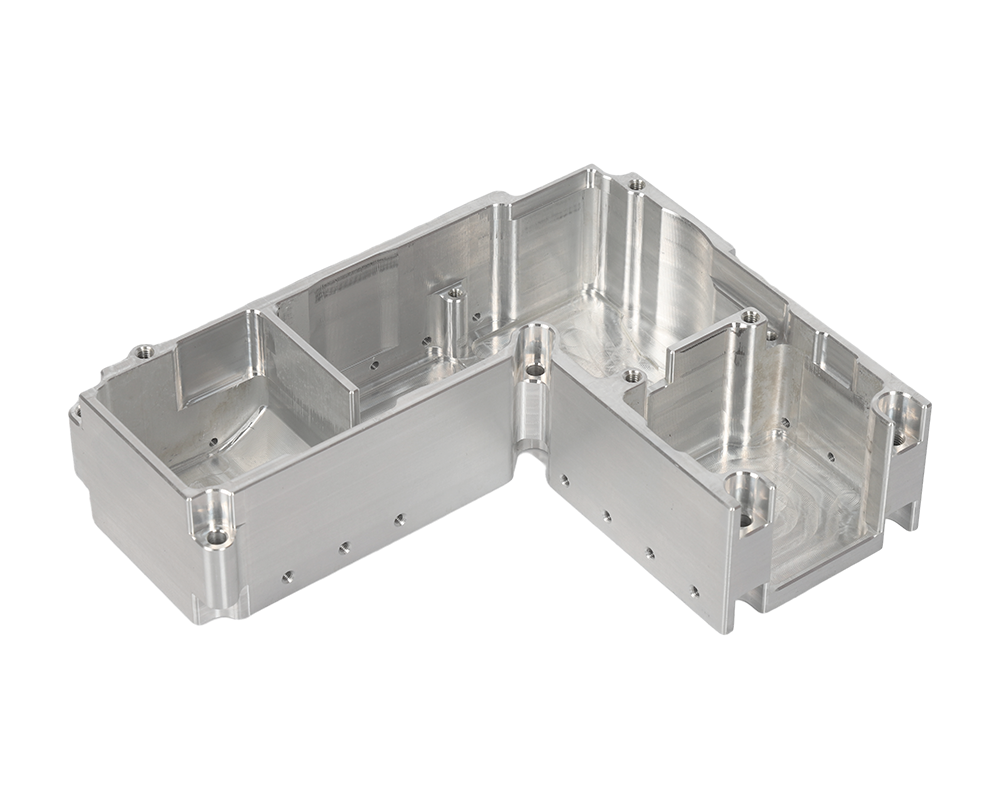

waterproof aluminum enclosure.Strength Testing Standards of Die Casting Products