2025-04-24 hits:0 source:corten steel fabricators

Designing aluminum profiles for home appliance shells involves a comprehensive consideration of multiple aspects, including functionality, aesthetics, durability, and manufacturing feasibility. Aluminum's lightweight, corrosion - resistant, and formable properties make it an ideal material for home appliance shells, but careful design is required to fully leverage these advantages.

Functionality is the primary consideration. Home appliance shells need to provide adequate protection for the internal components while facilitating proper operation. For example, in refrigerators, the aluminum profile shell must be designed to ensure good insulation, airtightness, and structural integrity. The design may incorporate features such as grooves and channels for installing seals, ensuring that cold air does not escape. In washing machines, the shell needs to withstand vibrations during operation, so the aluminum profile design may include reinforcing ribs or a specific structural layout to enhance stability. Additionally, the design should allow for easy access to components for maintenance and repair, which may involve creating removable panels or hatches.

Aesthetics play a crucial role in home appliance design. Aluminum profiles can be shaped and finished in various ways to create attractive and modern - looking shells. The surface finish of the aluminum, such as anodizing in different colors, powder coating, or polishing, can significantly enhance the visual appeal of the appliance. Designers often consider the overall style and decor trends of modern households. For instance, sleek, minimalist designs with smooth curves and clean lines are popular for contemporary kitchen appliances. The aluminum profile design may also incorporate elements like handles, control panels, and decorative trims that are not only functional but also contribute to the overall aesthetic harmony of the appliance.

Durability is essential for home appliance shells. Aluminum profiles need to be able to withstand daily use, potential impacts, and environmental factors. The thickness and strength of the aluminum profile are carefully selected based on the application requirements. Reinforcement techniques, such as adding additional layers or using composite materials in critical areas, can be employed to increase durability. For example, in the corners of a microwave oven shell, where impacts are more likely to occur, thicker or reinforced aluminum profiles may be used. The design should also account for thermal expansion and contraction, especially in appliances that generate heat, to prevent deformation over time.

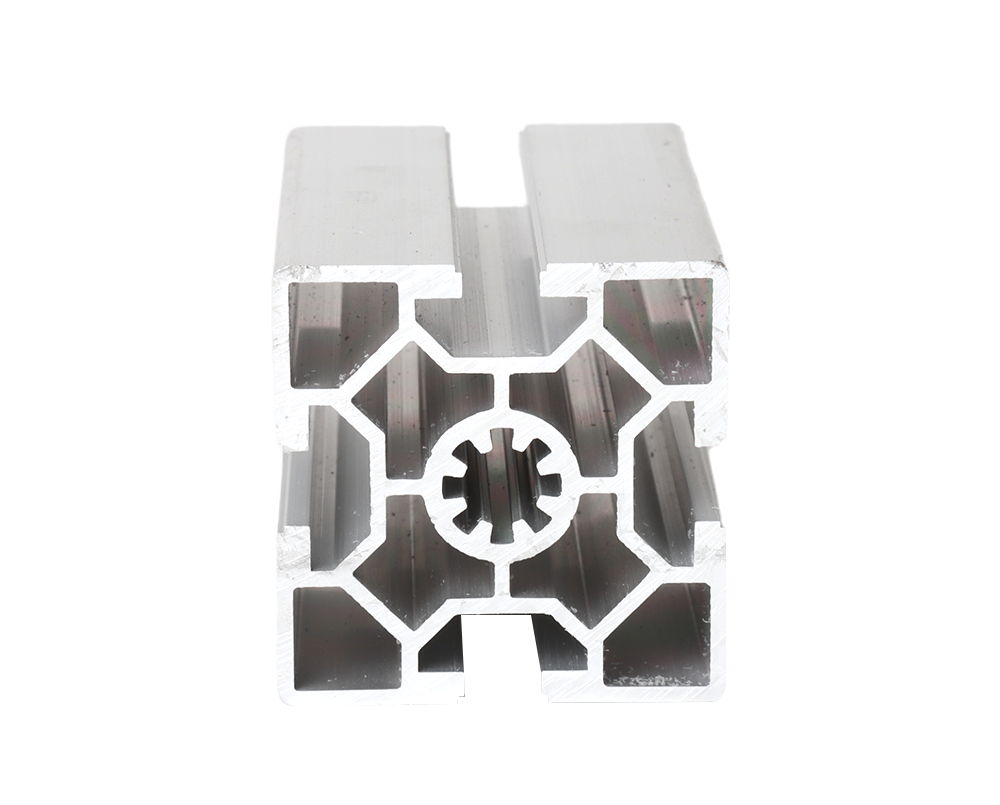

Manufacturing feasibility is another key aspect. The design of aluminum profiles for home appliance shells should be compatible with the manufacturing processes, such as extrusion, bending, and cutting. Complex designs that are difficult to manufacture may increase production costs and lead to quality issues. Designers work closely with manufacturers to ensure that the profiles can be produced efficiently and accurately. This may involve optimizing the cross - sectional shape of the profiles, reducing the number of complex bends, and using standard manufacturing techniques whenever possible. By carefully considering functionality, aesthetics, durability, and manufacturing feasibility, aluminum profiles can be designed to create high - quality, appealing, and practical home appliance shells.

Read recommendations: