2024-07-27 hits:0 source:corten steel fabricators

To make good die-casting molds, material inspection is essential

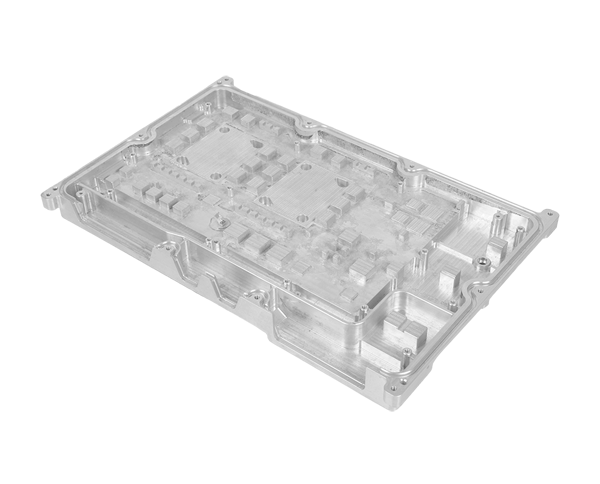

Die casting molds are essential tools for producing die-casting parts, directly affecting the quality and production efficiency of die-casting parts. At the same time, the production cost of die-casting molds is not low. Everyone who needs to open a mold hopes to produce high-quality die-casting molds with limited costs. So, how can we achieve this goal?

To achieve the above goals, it is essential to inspect the materials used in the production of die-casting molds. Die casting molds require long-term exposure to high-pressure and high-temperature working environments, which places high demands on the materials used for mold production. There are usually three methods for material inspection, namely macroscopic corrosion inspection, metallographic inspection, and ultrasonic inspection.

Macroscopic corrosion inspection can be used to detect defects such as porosity, segregation, cracking, and fissures in materials; Metallographic examination can be used to examine the segregation, distribution, grain size, and intergranular inclusions of carbides at grain boundaries in materials; Ultrasonic waves can be used to inspect defects and their sizes inside materials.

Read recommendations: