2024-07-25 hits:0 source:corten steel fabricators

Die casting factory helps you distinguish between decompression casting

machines

The most valuable equipment in a die-casting factory is the die-casting machine. Even the best ones cost hundreds of thousands, which can be regarded as a symbol of strength. The die-casting factory tells you that die-casting machines are also classified. According to different working modes, die-casting machines can be divided into cold chamber die-casting machines and hot chamber die-casting machines. So, what are the differences in the working modes of these two types of die-casting machines?

The die-casting factory informs you that the injection chamber of the cold chamber die-casting machine and the insulation furnace for the metal liquid are separate. The metal liquid needs to be injected from the furnace into the injection chamber of the cold chamber die-casting machine, and then injected into the mold cavity through the injection nozzle of the die-casting machine for cooling and forming; The injection chamber of the hot chamber die-casting machine is immersed in liquid metal and connected to the mold cavity through a gooseneck bottle. The liquid metal remains in the injection chamber until the die-casting piston pushes it into the mold cavity. Due to the high melting point of die-casting aluminum alloy, it is easy to damage the mold. Therefore, cold chamber die-casting machines are used for aluminum alloy die-casting, and hot chamber die-casting machines are used for zinc alloy die-casting.

Read recommendations:

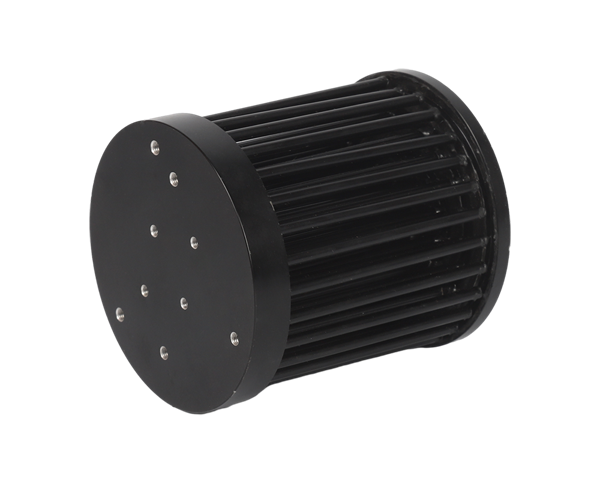

Aluminum electrical junction boxes with high - capacity cable entry points