2024-12-24 hits:0 source:News

Die casting is a manufacturing process in which molten metal, typically a non-ferrous alloy like aluminum or zinc, is injected into a mold or die to create precise and complex metal parts.

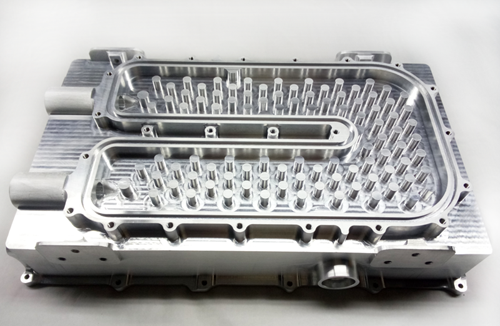

Die Casting Mold Overview

Die casting works by injecting molten metal into a die or mold. Mold design and manufacturing are crucial elements of the die-casting process. The mold cavity is created using two hardened/tempered steel or cast-iron dies machined to the desired part’s net shape. Pressure die casting involves injecting molten metal into the die cavity at high pressures and speeds, whereas low-pressure die-casting molds and gravity die-casting molds are filled at a much slower pace.

Low-pressure die casting is typically less expensive (requires less tooling) and results in lower levels of cast porosity. However, high-pressure die casting should be used for parts with thin walls (less than 3 mm thick) due to the ability of high pressure to force molten metal into the thin mold cavities. Once the molten metal is injected into the mold, it solidifies quickly, producing complex and detailed parts with high dimensional accuracy.

Two types of die casting

Die casting can also be classified based on the temperature of the mold or chamber. The two most common metal die casting methods classified by temperature are cold chamber die casting and hot chamber die casting.

Cold-Chamber Die Casting

Cold-chamber die casting involves introducing molten metal at room temperature into a separate shot chamber using a ladle or pouring method. The shot chamber contains a ram that vertically forces the molten metal into a steel mold (die) with movable and fixed sections. The ram applies pressure ranging from 2,000 to 20,000 PSI to propel the molten metal into the die. The pressure is maintained until the metal cools and solidifies, after which the finished product is ejected from the die. This method is suitable for high-melting-temperature alloys like aluminum.

Hot-Chamber Die Casting

Hot-chamber die casting is a metal casting process specifically designed for low-melting-point alloys like zinc, tin, lead, and magnesium. This process is the most common and faster method than cold-chamber die casting. In this method, the metal is melted within the casting machine, in a furnace connected to the machine. A hydraulic system injects molten metal into the die under high pressure. This process is efficient for producing intricate shapes with high-quality materials that have lower melting points. Still, it is not suitable for alloys with higher melting points due to the risk of damaging the pump that injects the molten metal.

What Are the Steps Involved in Die Casting?

Die casting involves the following steps:

Preparing the Die: The first step is to create the die. Dies are typically made from steel and are designed to endure high temperatures and pressures. The mold design starts with a CAD (computer-aided design) drawing of the mold. This file is used to make the mold using CNC (computer numerical control) machining. After the die is made, it is prepared with a releasing agent or lubricant. This helps release the cast part. The die is then clamped and closed with high pressure.

1.Metal Preparation: In the next step, the metal is prepared for the injection process. The metal, typically an aluminum, zinc, or magnesium alloy, is melted using a furnace and poured in a ladle.

2.Metal Injection: The molten metal is poured into the shot chamber. This chamber is hot for hot-chamber die casting and cold for cold-chamber die casting. After that, the molten metal is injected into the die using high pressure.

3.Cooling: The mold is allowed to cool and solidify into the shape of the mold.

4.Ejection: After cooling, the part will be hard and completely solid and can be removed from the die.

5.Trimming: The final step of die casting is the trimming step. This involves removing any excess metal found on the product. This is done by using a saw or trim die.

What Are the Most Suitable Materials for Die Casting?

Many different metals (primarily nonferrous alloys) are compatible with die casting. The three most common materials are:

Aluminum Alloys

Aluminum alloys are widely employed in die casting due to their unique properties. Notable alloys such as 380, 360, 390, and 413 exhibit high operating temperatures, outstanding corrosion resistance, low density, excellent strength, and good thermal conductivity. Additionally, aluminum alloys offer good stiffness, a favorable strength-to-weight ratio, EMI and RFI shielding properties, and recyclability. They can also withstand high temperatures and retain dimensional stability with thin walls.

Zinc Alloys

Zinc alloys, including Zamak #2, #3, #5, #7, ZA8, and ZA27, offer a balance of strength, toughness, firmness, and cost-effectiveness. These alloys are known for their improved castability, shortened cycle time, and extended die life. The mechanical qualities of zinc alloys rival and exceed other common die-casting materials such as aluminum, magnesium, and bronze. Their exceptional casting fluidity contributes to thin-wall castability, resulting in smaller, lighter, cost-effective components.

Magnesium Alloys

Magnesium, particularly the AZ91D alloy, stands out for its toughness, durability, lightweight nature, and good castability. With a weight 75% lighter than steel and 33% lighter than aluminum without compromising strength, magnesium alloys are preferred for applications requiring complex casting with tight tolerances. The material’s excellent corrosion resistance further enhances its appeal. Magnesium alloys in die casting offer a valuable combination of strength and weight reduction, making them suitable for various industrial and automotive components.

Other Die Casting Alloys

Besides the primary materials, die casting can involve other alloys such as bronze, copper, brass, lead, and tin. Tin, for example, is known for its high fluidity and low melting point, leaving minimal wear on molds. On the other hand, bronze, specifically white bronze, finds application in the jewelry industry due to its low melting point, resembling white gold and stainless-steel alloys.

Advantages and Disadvantages of Die Casting

Advantages of Die Casting

1.Short Lead Time: A typical casting cycle of a die casting process is very short. In fact, depending on size and material properties, it can be as low as a few seconds only.

2.Economical: Die casting is very economical for large batches of production. With time, the cost per part becomes surprisingly low.

3.Good Mechanical Properties: While not as strong as forged parts, die casting yields excellent mechanical strength. It can yield parts with enhanced durability, hardness, and conductivity as well.

4.Complex Details: You can manufacture complex parts in a very short period with die casting.

Excellent Precision: Die casting offers tighter tolerances than most other manufacturing techniques. Thus, it is suitable for many delicate applications.

5.Superior Finishing: You can design Die casting parts to have a smooth or textured finishing according to your requirements.

Disadvantages of Die Casting

1.Support Non-Ferrous Metals Only: It is a major drawback of die casting. Casting ferrous metal is not impossible, but manufacturers normally don’t prefer it due to the complexity.

2.Very High Initial Investment: A reason why many small companies and startups can’t afford to die casting is the extremely high initial investment.

3.Prone to Defects: Die casting parts are prone to defects such as porosity, misruns, cold shuts, etc., unless carefully designed.

4.Not Suitable for Small Scale Projects: Most big suppliers aren’t interested in providing die casting solutions for small-scale projects. Often, it ends up being costlier than other methods.

Die Casting Services

Die casting is a popular metal fabrication process due to its accuracy, efficiency, and low cost. Although pretty straightforward, this process requires expert knowledge and experience, which makes outsourcing to the right manufacturing service provider essential. Greenway consists of a team of knowledgeable and experienced engineers. We pride ourselves on delivering the best quality products according to our customers’needs. We encourage you to contact us for a free quotation at Harvey@greenwayalu.com and we will give you professional services for your next project.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible