The static reactive power compensation device (SVC) is a kind of important equipment for comprehensively controlling voltage fluctuation, flicker, harmonic and voltage imbalance. SVG is a new static reactive power compensation device which is more advanced than SVC. It is an important part of FACTS technology and custom power (CP) technology. It is the development direction of modern reactive power compensation device. They are widely used in power transmission and distribution systems: long-distance power transmission, urban secondary substation (35/110kv), arc furnace, mill hoist and other heavy industry loads, regional power grid, pv power supply, wind farm, electric locomotive power supply and other fields. SVG is a high-heat element, which needs to be combined with a radiator with excellent heat dissipation performance to ensure the stable operation of other elements and increase the working time.

Ambient temperature: 40℃

Altitude: 3000m

Assume IGBT model: Infineon IHV IGBT, 1250W/pcs, Common2pcs, Resistor body100W, total 2600W.

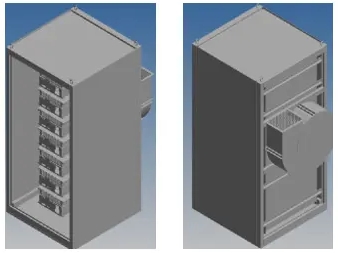

Module Power and Number: 7, Total power is 2600*7=18200W

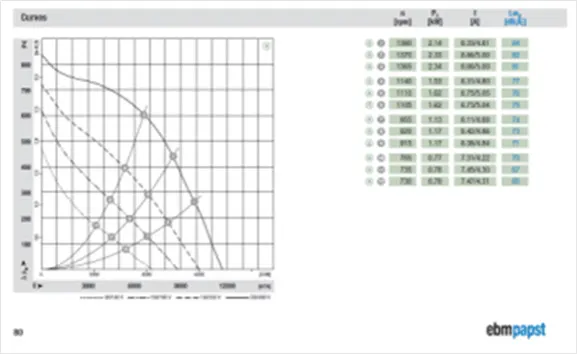

Style and type: R4D560-AQ03-01

Overall temperature requirements: <35℃

Heat Dissipating Medium Model: 10.2mm, K=4W/m*K

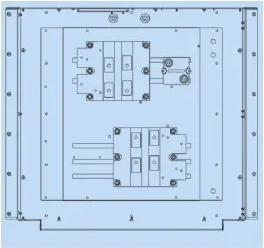

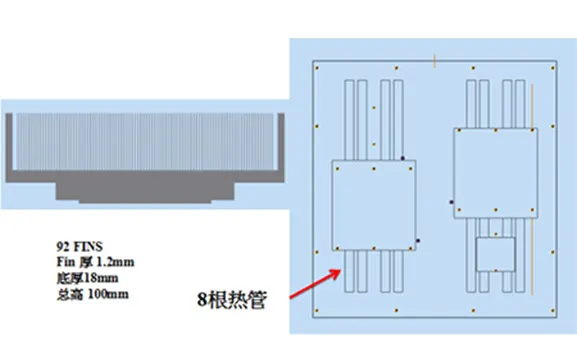

· The radiator size is 400x380x100mm,Specific Design of Heat Pipe Distribution;

· Use thermal conductive silicone grease between heater and radiator;

· Using wall thickness 1.0MM Customized heat pipe to ensure heat dissipation efficiency;

· 8 branches at the bottom 9.5 mm Heat pipes are grooved and flattened to ensure heat dissipation efficiency;

· Thermal analysis Epoxy thermal conductivity is adjusted to the corresponding data of working limit temperature to ensure the consistency between simulation and practice;

· All-aluminium radiator Bonded;

· The single weight of the product is about 10%.:22.6Kg;

· Bottom plate FIN Use of tablets AL5052 Thermal conductivity:138 w/m^2 K;

The parameters of radiator fan are as follows

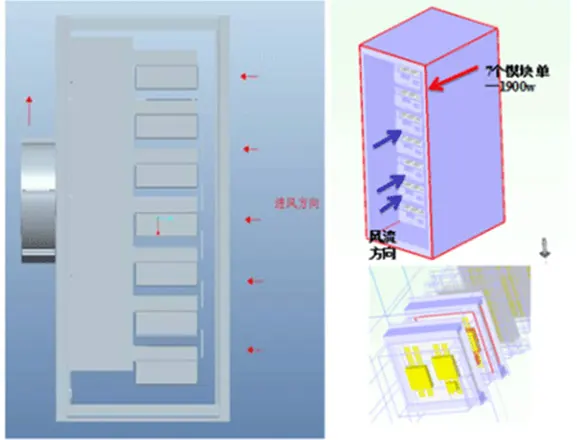

Plane schematic diagram of radiator form

Simulation sketch of radiator inlet and outlet air

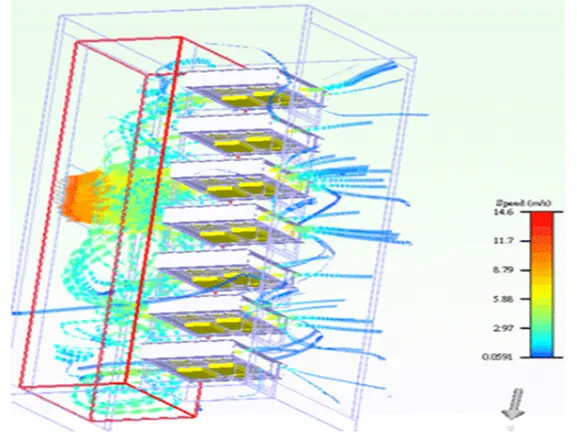

Drawing of Wind Flow Simulation

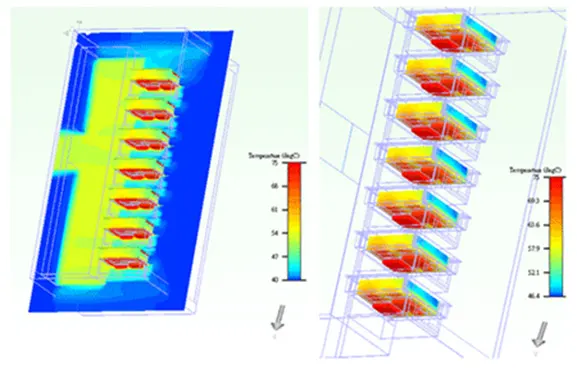

Temperature simulation sketch of radiator

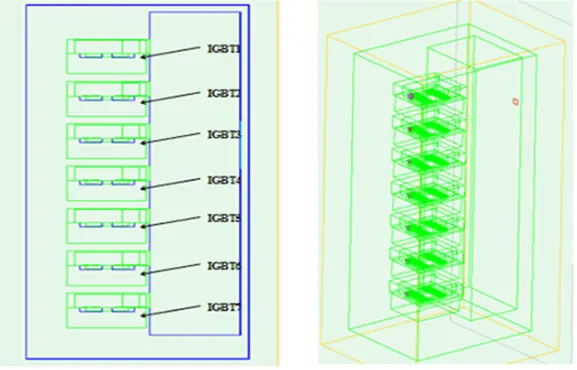

Simulating schematic diagram of temperature measuring point of radiator