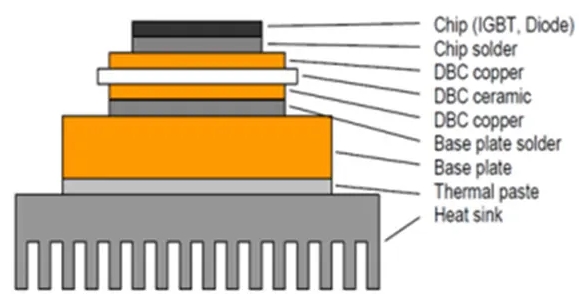

VFD is a kind of power control equipment which USES frequency conversion technology and microelectronic technology to control ac motor by changing the working power frequency of the motor. It is mainly composed of rectifier (ac to dc), filter, inverter (dc to ac), brake unit, drive unit, detection unit and micro-processing unit. VFD relies on the cut-off of internal IGBT to adjust the output power supply voltage and frequency. According to the actual needs of the motor to provide its required power supply voltage, then achieve the purpose of energy saving, speed regulation.

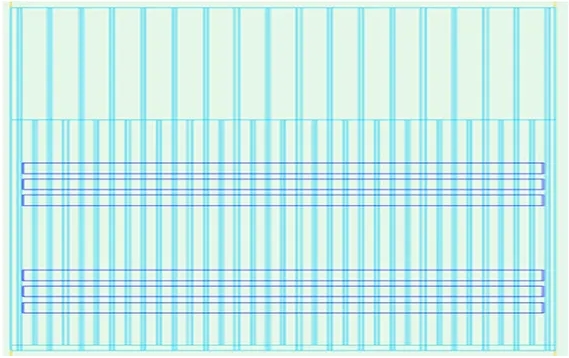

Substrate size:230*320*14mm;

Bonding fin: Thick15mm, High72mm;

Shorter fin: length 210mm,offset 5mm,17fins;

Longer fins: length:320mm, 18fins;

Total 35fins

Heat pipe parameters:

D9.5 Heat pipe;

Embedded tube is embedded on the bottom of heat dissipation base plate; 6pcs,pitch 12mm;

Epoxy resin bonding: K>=4W/m*K

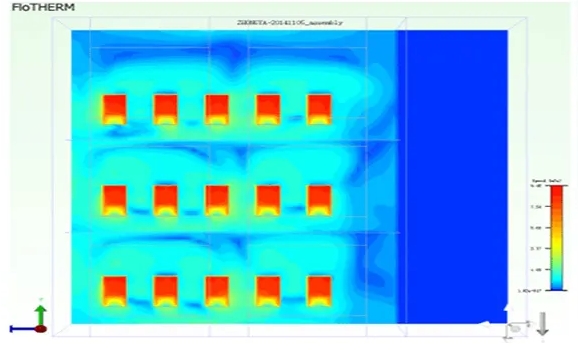

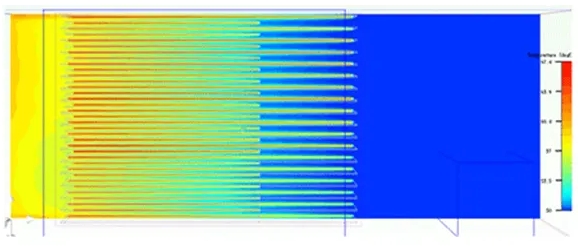

Simulating sketch of velocity diffusion degree of module intake airflow

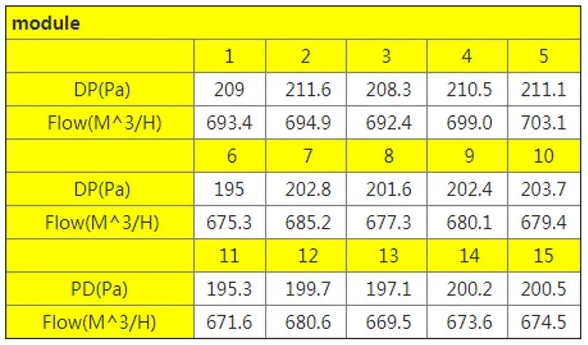

Minimum airflow:669.5m^3/H Maximum airflow:703.1m^3/H

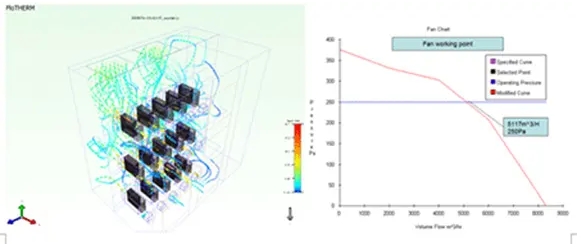

Simulation results of heat dissipation of converter module model and schematic diagram of fan working point

Temperature Diffusion of Cross Section in Inverter Radiator (Minimum Flow Module)

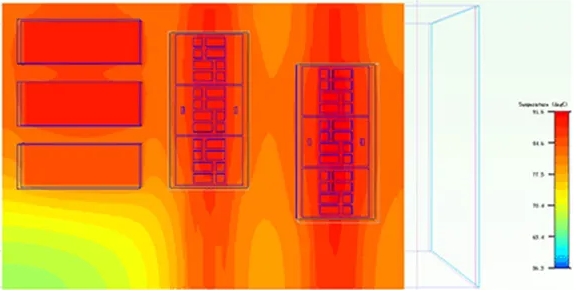

Temperature simulation sketch of winding

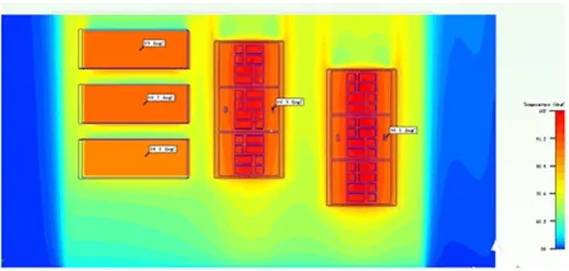

Temperature simulation sketch of winding